Laser Wood Cutting Machine – Precision and Efficiency for Woodworking

In today’s manufacturing world, precision and efficiency are crucial for success. Industries dealing with wood require advanced machines that can handle intricate designs while ensuring consistent performance. Laser Wood Cutting Machine technology offered by Laser Machine Manufacturers provides high-quality cutting solutions, combining accuracy, speed, and versatility for modern woodworking applications.

Laser Wood Cutting Machine for Enhanced Productivity

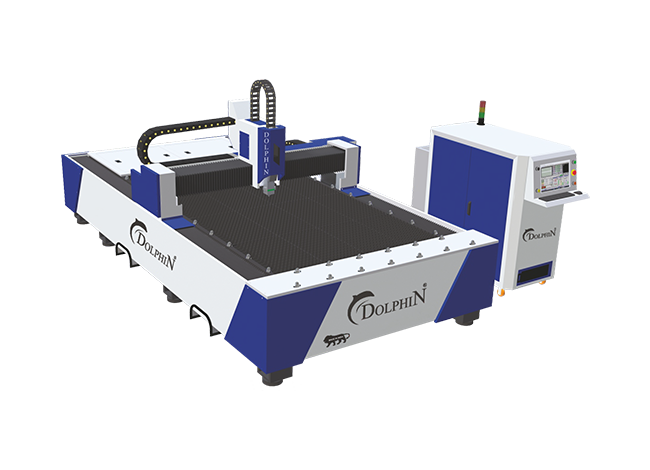

The modern Laser Wood Cutting Machine is designed to deliver superior performance in wood processing industries. These machines utilize advanced laser technology to cut, engrave, and shape wood materials with remarkable precision, outperforming traditional mechanical tools.

Laser Machine Manufacturers focus on building machines that optimize production workflows. With a user-friendly interface and precise cutting capabilities, the Laser Wood Cutting Machine helps operators reduce material wastage, improve design accuracy, and maintain high-quality output for each project.

Laser Wood Cutting Machine – Versatile Material Applications

A significant advantage of the Laser Wood Cutting Machine is its ability to work on a variety of wooden materials. From plywood and MDF to solid wood and laminates, these machines handle different thicknesses and textures efficiently. This versatility allows woodworking businesses to expand their product range without investing in multiple machines.

Advanced control systems provided by Laser Machine Manufacturers enable operators to adjust cutting speed, power, and engraving depth according to the material type. This flexibility ensures that each cut or engraving maintains precision, delivering consistent quality throughout production.

Benefits of Using a Laser Wood Cutting Machine

Investing in a Laser Wood Cutting Machine brings numerous advantages to woodworking industries. First, it significantly increases productivity. The high-speed laser operation reduces cutting and engraving time, allowing manufacturers to meet tight deadlines efficiently.

Second, the machine enhances product quality. Smooth edges, accurate cuts, and uniform engravings eliminate the need for secondary finishing processes, reducing labor and operational costs.

Third, these machines improve safety. Laser Machine Manufacturers equip them with protective enclosures and automated controls, minimizing the risk of accidents while simplifying operation for staff.

Finally, customization is easier than ever. Businesses can create intricate patterns, personalized wood products, and prototypes quickly, unlocking new avenues for creativity and innovation.

Laser Wood Cutting Machine – Energy Efficiency and Sustainability

Modern manufacturing emphasizes energy efficiency and sustainability. The Laser Wood Cutting Machine is designed to optimize power consumption while delivering high performance. By reducing energy usage, businesses can lower operational costs and contribute to environmentally responsible production practices.

Additionally, precise laser cutting minimizes material wastage, maximizing the use of raw materials and reducing environmental impact. By combining efficiency, precision, and sustainability, these machines offer both economic and ecological benefits.

Laser Wood Cutting Machine – Easy Maintenance and Longevity

Durability and low maintenance are essential for any industrial equipment. Machines from Laser Wood Cutting Machine manufacturers are built with robust components that ensure long-lasting performance. Routine maintenance is straightforward and does not require extensive technical knowledge, reducing downtime and ensuring uninterrupted production.

Laser Machine Manufacturers also provide comprehensive support and guidance, ensuring that the Laser Wood Cutting Machine remains reliable throughout its operational life. This consistency protects the investment and helps businesses maintain high productivity levels.

Laser Wood Cutting Machine – Ideal for Small and Large Workshops

Whether for small-scale workshops or large industrial units, the Laser Wood Cutting Machine offers scalable solutions. Small businesses can utilize the machine for customized products and intricate designs, while large manufacturers can maintain high-volume production with consistent precision.

The flexibility and adaptability of these machines allow businesses to expand operations without additional investment in multiple devices. One versatile solution meets diverse requirements, making it a cost-effective choice for woodworking industries of all sizes.

Key Features to Consider from Laser Wood Cutting Machine Manufacturers

When selecting a Laser Wood Cutting Machine, it is important to consider factors such as laser power, material compatibility, software features, and automation capabilities. Modern machines often include advanced control systems, automated feeding options, and high-speed cutting technology.

Laser Machine Manufacturers ensure that every machine meets industry standards for precision, performance, and safety. Businesses can integrate laser wood cutting technology seamlessly into their workflow, enhancing productivity and supporting innovation.

Conclusion – Laser Wood Cutting Machine by Laser Machine Manufacturers

In conclusion, the Laser Wood Cutting Machine by Laser Machine Manufacturers is an essential tool for woodworking industries seeking precision, efficiency, and versatility. With the ability to handle various wood types, reduce production time, and maintain consistent quality, these machines deliver significant advantages for manufacturers.

Investing in a Laser Wood Cutting Machine ensures improved productivity, lower operational costs, and scalable solutions for workshops of all sizes. The combination of precision, durability, and energy efficiency makes it an ideal choice for businesses looking to stay competitive in today’s demanding market.